Introduction

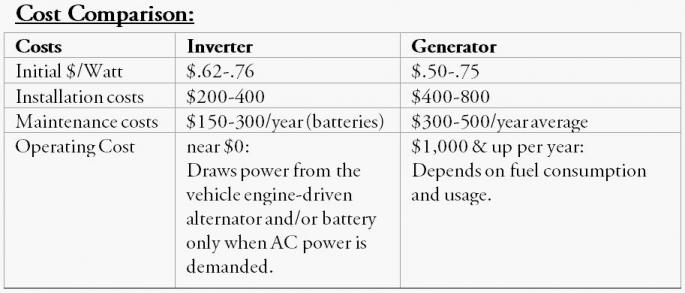

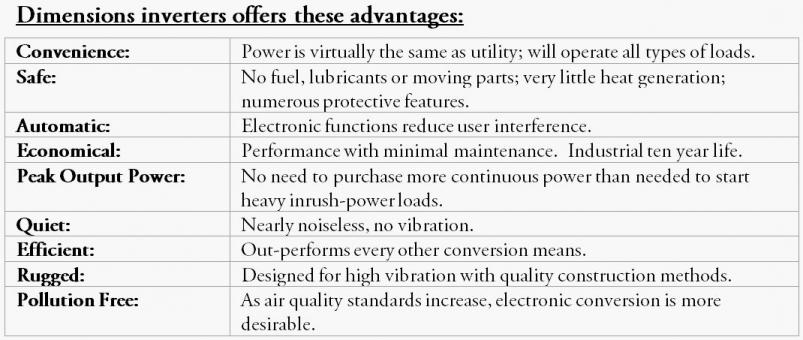

In most cases, Power Inverters offer superior performance and significant cost savings when compared to generators on Utility Service Vehicles. In general, the more that a load requires high inrush current with lower running power, such as an air compressor, water pump or electro-fusion - the more favorable an inverter is for use in that situation. Generators may be favored only where loads require little or no peak power and high levels of running power (above 5 KW), such as a large heater, or on for long time periods of time. When compared with modern, solid state Dimensions Power Inverters, generators have definite drawbacks in the areas discussed below.

Peak Output Power

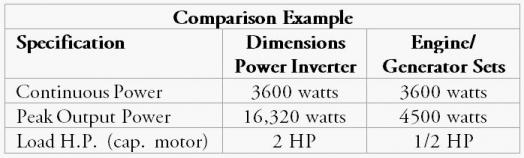

Peak output power or inrush current, is the ability of a power source to provide more than its rated power to start a load. Motor loads are especially demanding. They can require five to ten times their running power when starting. Generators have poor peak power capability due to their inherent operating characteristics. Peak power is usually no more than 110%-125% of their continuous power rating. They must be greatly oversized to successfully start some motor loads. On the other hand, because static inverters can take advantage of the large instantaneous power from a storage battery, they have very high peak capability, often three to four times their UL continuous power rating. There is normally no need to purchase an oversized inverter to run any given motor load. Magnum-Dimensions rates all inverters in horsepower to allow a comparison with engine generators.

Continuous Power

The continuous power rating is the ability of the power source to provide rated power for an indefinite time. All Magnum-Dimensions inverters use the UL rating method for continuous duty. If a larger than ideal generator is purchased to satisfy the load's peak or motor starting requirements, the excess generator capacity is wasted and will result in additional fuel consumption and reduced life.

Standby Power

Also known as idle or quiescent power draw, this is the minimum amount of power needed to "turn on" an inverter or generator. Obviously, this is much greater for a generator that has either little or no load - since a generator's engine must always be running resulting in; great inefficiency, noise, pollution, and wear. On the other hand, with little or no load, a Magnum-Dimensions inverter requires only 25-50 watts at idle; yet it can deliver full power instantly to loads when needed.

Output Frequency

Many loads, such as motor driven tools, will not operate over a wide frequency range. Output frequency of an engine generator is directly related to engine RPM; this can vary considerably. A Magnum-Dimensions inverter is precisely regulated to 60Hz over a wide range of operating conditions.

Output Voltage

Engine generators occasionally deliver voltages outside of the accepted ANSI range of 110-127VAC. These voltage excursions can damage loads. In contrast, Dimensions inverters closely match utility power and are consistently regulated to within the ANSI specification.

Maintenance

Generators require periodic maintenance to assure proper operation. The oil needs to be changed after every 200 hours of use. It is also highly recommended that if the generator will be stored for more than 30 days without use, that the fuel is drained and the carburetor run dry. Inverters require no maintenance other than inspecting your batteries once a year.